News

Why Regular Kalibraatio Improves Pressure Measurement Accuracy

Kalibraatio, commonly known as calibration, refers to the process of comparing the readings of a measurement instrument with a standard of known accuracy. The goal is to determine whether the instrument provides accurate readings and, if not, to make the necessary adjustments. In the context of pressure measurement, plays an essential role in ensuring that devices such as pressure gauges, transmitters, and sensors deliver reliable and precise data. Over time, environmental factors, mechanical wear, and operational conditions can cause instruments to drift from their true values. Regular corrects these deviations and guarantees that the equipment continues to perform according to its design specifications.

Importance of Kalibraatio in Industrial Applications

In industries where precision is critical, such as oil and gas, manufacturing, pharmaceuticals, and food processing, even a small error in pressure measurement can lead to significant consequences. Incorrect readings can cause poor process control, equipment damage, safety risks, and reduced product quality. By performing kalibraatio at regular intervals, organizations can minimize these risks and maintain operational efficiency. The practice of regular not only ensures accuracy but also helps in maintaining compliance with international standards such as ISO and IEC. These standards require periodic verification of measuring instruments to ensure that they function within acceptable error limits.

How Kalibraatio Enhances Pressure Measurement Accuracy

Pressure instruments are designed to measure the force exerted by a fluid per unit area. However, due to continuous use, exposure to harsh environments, or aging components, their accuracy can deteriorate. Kalibraatio helps identify these changes in measurement performance and allows technicians to recalibrate the instrument to restore its original accuracy. By comparing the device’s readings to a reference standard, deviations are detected and corrected. This process ensures that all measurements taken are consistent with national or international standards. The improved accuracy achieved through regular kalibraatio not only enhances process reliability but also supports better decision-making based on trustworthy data.

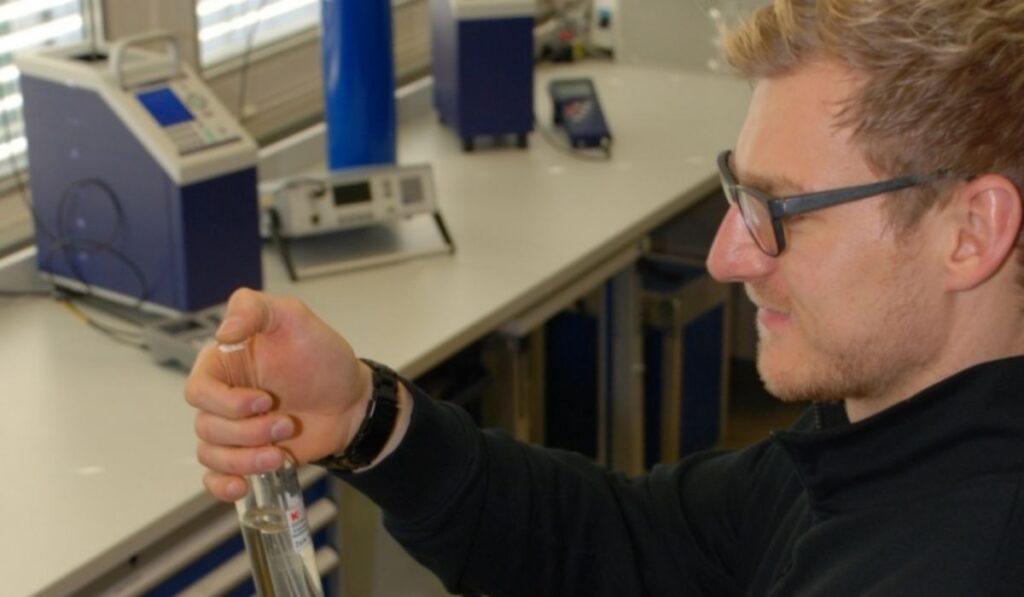

The Process of Performing Kalibraatio for Pressure Instruments

Kalibraatio of pressure instruments involves a systematic process that includes preparation, comparison, adjustment, and documentation. During the preparation stage, the equipment is cleaned, inspected, and set up under stable environmental conditions. Next, the pressure device is compared against a reference standard, such as a deadweight tester or a precision calibrator, which has been certified for accuracy. The readings of the device under test are recorded at multiple pressure points to evaluate its performance. If deviations are found beyond permissible limits, adjustments are made to bring the readings within acceptable accuracy levels. Finally, all results are documented to provide traceability and maintain records for quality assurance audits.

Benefits of Regular Kalibraatio for Organizations

The benefits of conducting regular kalibraatio extend far beyond maintaining measurement accuracy. It helps organizations reduce production errors, minimize waste, and avoid costly equipment downtime. In regulated industries, it ensures compliance with safety and quality standards, protecting both the company and its customers. Regular kalibraatio also extends the lifespan of pressure instruments, as it helps in early detection of wear and potential faults. Moreover, it improves energy efficiency by optimizing process control, since accurate pressure readings contribute to smoother operations and consistent performance. Ultimately, companies that invest in routine kalibraatio benefit from increased productivity, improved product quality, and enhanced reputation in the market.

Factors Affecting the Frequency of Kalibraatio

Determining how often kalibraatio should be performed depends on several factors, including the type of instrument, its usage conditions, and the required level of accuracy. Instruments operating in harsh or variable environments tend to drift faster and therefore require more frequent calibration. Similarly, equipment used in high-precision applications should be calibrated more regularly than those used in general-purpose operations. Manufacturer recommendations also play a significant role in setting calibration intervals. Additionally, organizations that adhere to quality management systems often establish internal policies that define calibration frequencies based on risk assessment and historical performance data.

The Impact of Neglecting Regular Kalibraatio

Failure to perform regular kalibraatio can have serious implications for both safety and performance. Instruments that are not properly calibrated may produce incorrect pressure readings, leading to unsafe working conditions or process failures. For example, in chemical or petroleum industries, inaccurate pressure data can result in leaks, explosions, or product contamination. In manufacturing, even minor deviations in pressure can affect material consistency and final product quality. Over time, the costs of operating with uncalibrated instruments far outweigh the investment required for routine kalibraatio. Neglecting calibration not only increases operational risks but can also lead to regulatory non-compliance and legal penalties.

The Role of Technology in Modern Kalibraatio

Advancements in technology have transformed the way kalibraatio is conducted. Automated calibration systems now allow for more precise, faster, and more reliable calibration processes. Digital pressure calibrators equipped with advanced sensors and software enable technicians to perform real-time data analysis and automatic error correction. Cloud-based calibration management systems also make it easier to store, track, and manage calibration records across multiple devices and locations. These technologies reduce human error and ensure consistent calibration quality. As industries move toward greater automation and digitalization, the integration of smart calibration solutions has become a key part of maintaining operational excellence.

Ensuring Traceability and Compliance Through Kalibraatio

Traceability is a critical component of the kalibraatio process. It ensures that every measurement result can be linked to an accepted national or international standard through an unbroken chain of comparisons. This is especially important in industries governed by strict regulatory frameworks, where documentation and traceability are required for audits and certifications. Properly maintained calibration records serve as proof that the equipment is performing within acceptable limits. In addition to demonstrating compliance, traceable kalibraatio fosters customer confidence by ensuring that all products and processes meet defined quality criteria. Regular documentation and verification of calibration results help organizations maintain a high standard of operational reliability.

The Future of Kalibraatio in Pressure Measurement

As industrial systems become more sophisticated, the importance of kalibraatio will continue to grow. The increasing use of automation, Internet of Things (IoT) devices, and data-driven manufacturing demands even higher accuracy and consistency in measurement systems. Predictive maintenance strategies are also beginning to incorporate calibration data to identify when instruments are likely to drift or fail, allowing for proactive servicing. Furthermore, remote calibration and self-calibrating instruments are emerging trends that promise to reduce downtime and enhance measurement reliability. The future of kalibraatio lies in combining traditional metrology principles with modern digital innovations to achieve seamless, accurate, and efficient measurement control.

Conclusion

Regular kalibraatio is not just a technical requirement but a critical practice that underpins the reliability, safety, and efficiency of pressure measurement systems. It ensures that instruments provide accurate and consistent readings, supporting better process control and decision-making. Organizations that prioritize routine calibration benefit from improved product quality, reduced operational risks, and compliance with international standards. As technology continues to advance, the methods and tools for kalibraatio will become even more precise and efficient. However, the fundamental principle remains the same—regular calibration is the key to maintaining accuracy and ensuring that every measurement truly reflects reality.

Frequently Asked Questions (FAQs)

1. What is the main purpose of kalibraatio?

- The primary purpose of kalibraatio is to ensure that measuring instruments provide accurate readings by comparing them against a standard reference and adjusting them as necessary.

2. How often should pressure instruments be calibrated?

- The frequency of kalibraatio depends on factors such as equipment usage, environmental conditions, manufacturer recommendations, and industry standards, but it is generally advised to calibrate at least once a year.

3. What happens if an instrument is not regularly calibrated?

- Without regular kalibraatio, instruments may produce inaccurate readings, leading to process errors, safety risks, poor product quality, and potential regulatory violations.

4. Can calibration be performed in-house?

- Yes, many organizations perform kalibraatio in-house if they have the necessary equipment, trained personnel, and reference standards. Otherwise, they can outsource calibration to accredited laboratories.

5. Why is documentation important in kalibraatio?

- Proper documentation ensures traceability, compliance with industry standards, and verification that all instruments are operating within acceptable accuracy limits. It also provides essential records for audits and quality control.

-

Celebrity8 months ago

Celebrity8 months agoThe Private World of Marina Pearl LeBlanc, Matt LeBlanc’s Only Child

-

Life Style1 year ago

Life Style1 year agoWho is Amra Nor Jenkins? The Untold Story About Jeezy’s Daughter

-

Entertainment1 year ago

Entertainment1 year agoWhat is Shoujo Ramune? The Comprehensive Guide

-

Celebrity1 year ago

Celebrity1 year agoThe Untold Truth of William Mapel: A Deep Dive into His Personal Life

-

Celebrity1 year ago

Celebrity1 year agoWho is Christina Erika Carandini Lee? Everything About Christopher Lee’s Daughter

-

News1 year ago

News1 year agoRanch World Ads Review: Everything You Need to Know

-

Celebrity1 year ago

Celebrity1 year agoWho Is Stephanie Sarkisian? All You Need To Know AboutSteve Sarkisian’s Ex-Wife

-

Celebrity1 year ago

Celebrity1 year agoThe Untold Story of Denika Kisty: Her Family, Net Worth, and More