News

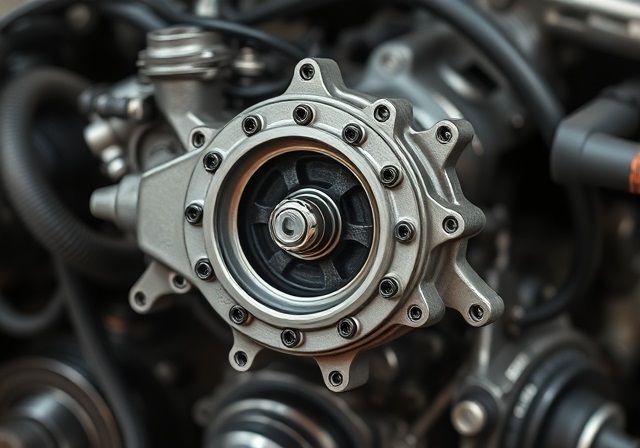

What You Need To Know About Oil Pump

An oil pump is a vital component in internal combustion engines, responsible for circulating oil under pressure to various engine parts, ensuring lubrication, cooling, and overall engine health. Understanding its function, types, and maintenance is essential for vehicle owners and enthusiasts.

What Is an Oil Pump?

An oil pump suctionates oil from the oil sump and charges the oil before it distributes it all over the engine. This process also greases parts such as crankshaft, pistons, and bearings to reduce friction, which in return causes less wear. Also, the oil cools the engine since the engine burns out a lot of heat and can easily detonate or cause great harm to the car. For instance, an oil pump failure can result in an engine heating up and seizing in as little as fifteen minutes and is irreparable.

Types of Oil Pumps

Various types of oil pumps are used in engines, each with unique mechanisms:

Gear Pumps: Due to the fact that its uses included the locomotion of oil, it employed interlocking gears consistently. The gears turn to pump, suck oil and then press out the oil at the end of a cycle. Gear pumps are no exception and are typically some of the most reliable and consistent ones in use today.

Trochoid Pumps: Include a special irregularly shaped blade that spins inside a corresponding enclosed space. This design is ideal for the free and unobstructed flow of oil commonly found in today’s modern engines due to the compact design and durability of this product line.

Vane Pumps: Comprise a plurality of vanes disposed on a rotor that translates into a casing. While the rotor is spinning, the vanes reciprocate to form chambers that suction and dispense oil. Although well used, vane pumps have disappeared because of their complicated design and the existence of superior technologies.

How Does an Oil Pump Work?

The oil pump, normally built with internal gears, a screen, or a chamber, works in pumping the oil from the sump with the help of a pickup tube that has a wire mesh screen or strainer that filters out the gravel. When the oil finds its way into the pump, it is compressed and then pushed through the oilways of the engine.

This pressurized oil goes to the main parts, such as bearings, pistons, and camshaft, for the required lubrication and cooling. Lubrication oil circulates through the engine, where it gets into contact with the metal components, and then the oil drips down to the sump before it is circulated again.

Importance of Oil Pressure

Oil pressure is very important and should always be kept Checked on a regular basis. The levels of oil pressure are built up from the pressure that is encountered by the oil after it has passed through the engine. If the pressure is low, it informs of either high leakage or excessive wear, which in turn leads to a lack of lubrication of the engine, along with considerable damage.

On the other hand, very high oil pressure can cause erosion of the seals and thereby lead to leaks. Normally, oil pressure should be 10 psi for every 1,000 rpm and can go up to 55-65 psi maximum. In the present time, many mechanisms are implemented and these routine visits make sure the oil pump works properly and there is a good oil pressure.

Wet and Dry Sump Systems

Engines utilize either wet or dry sump lubrication systems:

Wet Sump Systems: Known in most cars today, these systems have a single oil pump above the engine’s lower half directly below the crankshaft. The oil is kept in a pan under the given engine, and the pump directly takes the oil from this holding pan. Wet sump systems are relatively cheaper than dry sump systems, but in certain performance circumstances where there is movement of oil, the wet sump systems are better.

Dry Sump Systems: Well known in high-performance and motor racing engines, dry sump systems have at least two pumps: pumping and circulating oil and one more to scavenge it from the engine and pump to an attached tank. This design eliminates oil starvation during severe operational conditions and also facilitates better positioning of the engine within the automobile since the need for an oil pan is reduced. However, dry sump systems are vastly more complex and, hence, less affordable.

Common Issues and Maintenance

Wear and Tear: Sometimes the engine parts, such as the oil pump, may wear out, which may lead to low efficiency of the system. They argued that proper change of the oil, as well as the use of the right oil brand, can go a long way in reducing wear occasioned by high use of the vehicle.

Oil Contamination: There is dirt and scum which can settle on the bottom of the oil and may block the inlet of the pump. Contamination can be prevented by adopting the use of high quality oil and replacing the oil filters as often as required.

Oil Leaks: A leak that results in low oil levels puts extra strain on the pump and can lead to its failure. This means that the system is tightly sealed and functioning properly if leaks are found and addressed on a regular basis.

How to Choose the Right Oil Pump for Your Engine

It is well understood that choosing the right oil pump is a crucial decision because this is going to decide the long term performance of the vehicle as well as its durability. There are other factors that you should know About, such as the type of engine you have.

Specifically, high performance or racing engines may need more developed dry sumps that are capable of operating under certain conditions, while ordinary PU or pedestrian cars are appropriate for wet sumps. More importantly, the compatibility of the pump with the specifications of your engine, such as the oil flow rate and pressure, is important.

There is also the issue of the material and the structure of the pump on the side of the purchaser. When choosing the type of pump, choose a steel pump or an aluminum one so that they can withstand high temperatures and thus not easily corrode.

This is especially so if you are not certain of the capabilities of your particular oil pump and therefore it may be good to seek advice from the manufacturer of your vehicle or even a mechanic. Selecting a correct pump will help minimize friction, dissipate heat and save your engine from wearing out in the long run.

Signs of a Failing Oil Pump

Recognizing the symptoms of a failing oil pump can prevent severe engine damage:

Low Oil Pressure Warning Light: If this light illuminates, it may indicate that the oil pump is not maintaining adequate pressure.

Increased Engine Temperature: Insufficient oil circulation can lead to overheating.

Unusual Noises: Grinding or whining noises from the engine may suggest that moving parts are not receiving proper lubrication.

-

Celebrity8 months ago

Celebrity8 months agoThe Private World of Marina Pearl LeBlanc, Matt LeBlanc’s Only Child

-

Life Style1 year ago

Life Style1 year agoWho is Amra Nor Jenkins? The Untold Story About Jeezy’s Daughter

-

Entertainment1 year ago

Entertainment1 year agoWhat is Shoujo Ramune? The Comprehensive Guide

-

Celebrity1 year ago

Celebrity1 year agoThe Untold Truth of William Mapel: A Deep Dive into His Personal Life

-

Celebrity1 year ago

Celebrity1 year agoWho is Christina Erika Carandini Lee? Everything About Christopher Lee’s Daughter

-

News1 year ago

News1 year agoRanch World Ads Review: Everything You Need to Know

-

Celebrity1 year ago

Celebrity1 year agoWho Is Stephanie Sarkisian? All You Need To Know AboutSteve Sarkisian’s Ex-Wife

-

Celebrity1 year ago

Celebrity1 year agoThe Untold Story of Denika Kisty: Her Family, Net Worth, and More